Tired of fragile, heavy glasses that offer little protection? Discover the eyewear revolution! Polycarbonate eyeglasses are transforming how we see and protect our eyes, offering unparalleled impact resistance, inherent UV protection, and remarkable lightweight comfort. This advanced material ensures your vision is not only crystal clear but also incredibly safe and comfortable for daily wear, active lifestyles, and even as durable prescribed sunglasses. Uncover how this innovative lens solution solves common eyewear frustrations, providing lasting value and peace of mind.

What Are Polycarbonate Eyeglasses?

The Material Revolutionizing Eyewear

Polycarbonate eyeglasses represent a significant leap in optical technology. For decades, wearers sought lighter, stronger, and more protective lenses. The advent of polycarbonate materials has delivered precisely that, transforming how we perceive and use corrective eyewear. This section delves into what makes this material so groundbreaking for vision correction.

Definition and Composition: Polycarbonate Lenses

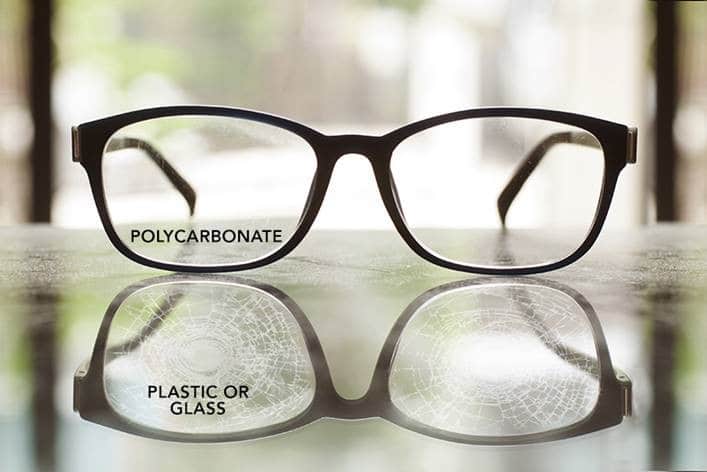

At its core, a polycarbonate lens is crafted from a sophisticated thermoplastic polymer. This material is renowned for its exceptional strength-to-weight ratio and outstanding impact resistance. Unlike traditional glass or standard plastic (CR-39) lenses, polycarbonate’s molecular structure allows it to absorb significant energy without shattering.

Consider its applications beyond polycarbonate eyeglasses: this robust material is integral to products demanding extreme durability. It is widely used in everything from motorcycle helmet visors and safety goggles to compact discs and even bulletproof glass. Such diverse, high-stakes uses underscore the inherent resilience and protective qualities of polycarbonate as an eyewear material. Its unique lens composition ensures superior impact resistance, making it a top choice for protective eyewear.

A Brief History of Eyewear Technology

For many years, glass and then standard plastic lenses dominated the eyewear technology landscape. While functional, both had significant drawbacks. Glass lenses were heavy and prone to shattering into dangerous shards upon impact. Standard plastic lenses were lighter but still lacked the impact resistance needed for active lifestyles or safety-conscious environments.

The late 20th century marked a pivotal moment with the emergence of polycarbonate lenses. Originally developed for aerospace applications, this material quickly found its way into commercial products, including optics. Why did it become so popular? Polycarbonate offered a dramatically safer, lighter alternative to its predecessors. This lens innovation meant improved safety for children, athletes, and anyone seeking enhanced protection for their eyes. It ushered in an evolution of eyewear technology, prioritizing not just visual acuity but also the comfort and security of the wearer.

Why Polycarbonate is a Go-To Choice

In the vast world of prescription eyewear, polycarbonate eyeglasses have emerged as a dominant force. Their multifaceted benefits address many common concerns wearers have, from comfort and aesthetics to safety and longevity. This makes them a preferred option for a broad spectrum of users in 2025.

Core Benefits of Polycarbonate Eyeglasses

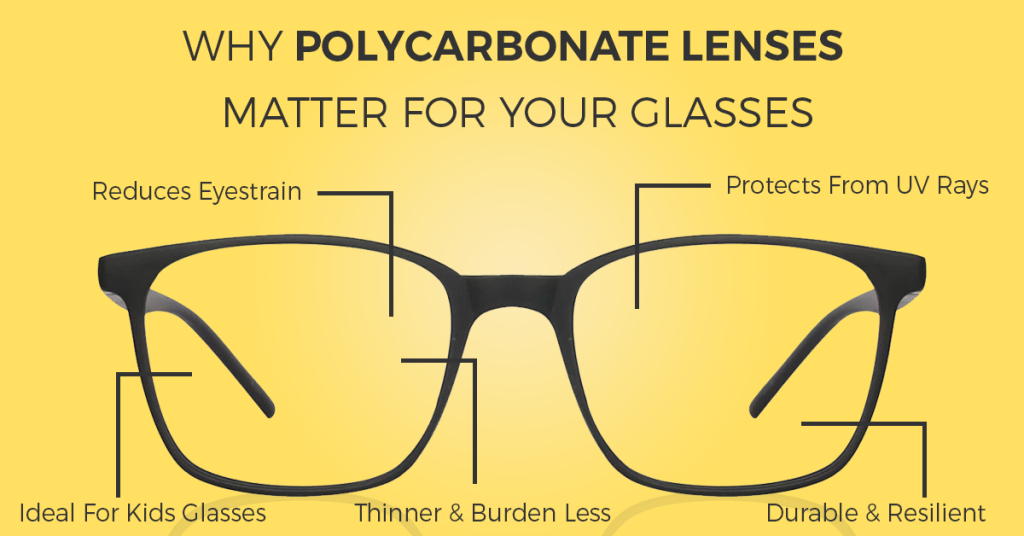

One of the most immediate advantages of opting for polycarbonate eyewear is its remarkable lightness. Compared to conventional glass or plastic lenses with the same prescription, lightweight polycarbonate significantly reduces overall weight. This translates directly into enhanced comfort for daily wear, minimizing pressure points on the nose and ears. No longer do wearers have to contend with heavy frames that slide down or cause discomfort throughout the day.

A common question is: Are polycarbonate lenses thin? The answer is a resounding yes. They are inherently thinner than standard plastic lenses, especially for higher prescriptions. This is due to their higher refractive index, meaning they bend light more efficiently. A thinner profile not only improves the aesthetic appeal of your polycarbonate frames but also reduces the “bug-eye” effect often associated with stronger prescriptions.

Beyond lightness and thinness, the enhanced durability of polycarbonate eyewear is perhaps its most celebrated attribute. These lenses are incredibly impact resistant, making them an ideal choice for active individuals, children, and anyone whose occupation or hobby puts their eyes at risk. Whether it’s a casual drop, an accidental bump, or protection during sports, polycarbonate lenses offer superior safety glasses capabilities. This robust nature ensures your polycarbonate eyeglasses can withstand the rigors of daily wear and active lifestyles. For those who rely on specialized vision correction such as reading glasses, understanding lens material is crucial. If you’re exploring options for specific vision needs, for instance, learning about various powers and materials can dramatically improve your experience; explore more about how different lens strengths, such as those found in 1.25 reading glasses, can conquer blurry vision and enhance your daily tasks.

Choosing polycarbonate eyeglasses means investing in a blend of comfort, sleek design, and unparalleled protection. To explore a wide range of polycarbonate frames and lenses that combine these benefits, you can visit polycarbonate eyeglasses. This collection offers various styles and prescriptions that leverage the cutting-edge properties of polycarbonate, ensuring your eyes are well-protected and your vision is clear.

Unpacking the Benefits of Polycarbonate Lenses

Building on our understanding of what polycarbonate eyeglasses are, it’s time to explore the compelling reasons behind their widespread adoption. In 2025, discerning eyewear users consistently choose this material for its unparalleled combination of safety, vision protection, and wearer comfort. This section breaks down the core advantages that make polycarbonate lenses a superior choice for a diverse range of needs.

Superior Impact Resistance & Safety

The inherent strength of polycarbonate is not just a feature; it’s a fundamental promise of safety for your eyes. This material excels where traditional lenses falter, offering robust protection against unexpected impacts.

Protecting Your Eyes: Impact Resistance Polycarbonate Lenses

When it comes to eye protection, polycarbonate lenses set the standard. These lenses consistently meet and often exceed rigorous safety certifications, such as the ANSI Z87.1 standard for safety eyeglasses. This compliance means they undergo stringent testing to withstand high-velocity and high-mass impacts, significantly reducing the risk of eye injury from flying debris or blunt force.

Consider the extreme durability: polycarbonate offers ballistic impact protection. For instance, high-performance eyewear brands utilize polycarbonate compounds (like Oakley’s Plutonite) engineered to stop projectiles as potent as a 0.15 caliber projectile traveling at 640 feet per second. This level of impact resistance is testament to the material’s structural integrity, making polycarbonate lenses an excellent choice for protective eyewear in various environments.

Ideal for Active Lifestyles and Kids

Given their exceptional resilience, it’s no surprise why polycarbonate glasses for kids are so widely recommended by opticians and pediatricians. Children, with their active play and occasional tumbles, require lenses that can withstand rough handling without shattering. Polycarbonate provides this peace of mind, minimizing the risk of lens-related injuries during sports, playground activities, or even everyday accidents.

Beyond children, polycarbonate eyeglasses are crucial for sports enthusiasts and those working in hazardous environments. Whether on the basketball court, cycling trail, or in a workshop, impact-resistant lenses guard against unforeseen hazards. For individuals seeking lightweight, durable vision correction that can withstand the demands of a dynamic life, including those who prefer streamlined designs for close-up tasks, exploring options like no frame reading glasses made from resilient materials offers both practicality and style. This focus on durability and safety makes polycarbonate the go-to material for active living.

Crucial UV Protection and Optical Clarity

Beyond their impressive strength, polycarbonate lenses also offer vital protection against harmful solar radiation and deliver more than sufficient visual performance for daily wear.

Blocking Harmful Rays: UV Protection in Polycarbonate Glasses

One of the often-underestimated benefits of polycarbonate is its inherent ability to block harmful ultraviolet (UV) radiation. Unlike other lens materials that require an added coating, polycarbonate lenses naturally provide virtually 99.9% protection against UVA, UVB, and even some UVC rays. This integrated UV protection is essential for long-term eye health, safeguarding against conditions like cataracts, macular degeneration, and other sun-related eye damage. This critical feature makes polycarbonate eyeglasses a popular choice for sunglasses, ensuring your eyes are shielded from the sun’s relentless assault, whether you’re indoors or out.

Understanding Optical Clarity of Polycarbonate

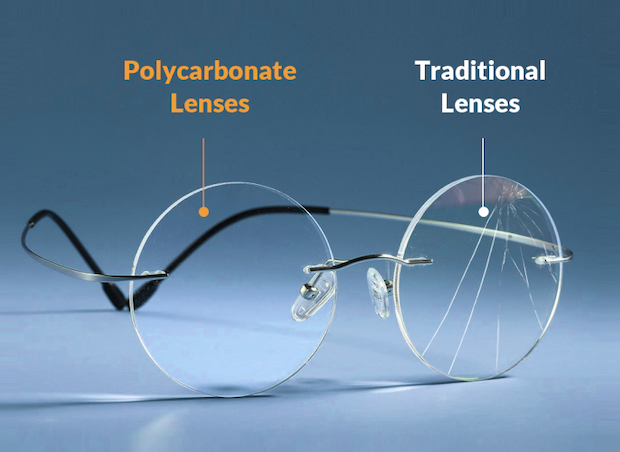

While polycarbonate lenses are renowned for their safety, a common question arises regarding their optical clarity. Historically, polycarbonate was considered slightly less optically clear than traditional glass or CR-39 plastic due to a phenomenon known as chromatic aberration. However, for the vast majority of users, this subtle difference is imperceptible and is certainly sufficient for prescription eyeglasses.

Furthermore, advancements in lens technology have significantly mitigated these issues. Leading eyewear manufacturers employ sophisticated designs and manufacturing processes, such as Oakley’s Polaric Ellipsoid geometry, to minimize distortion and optimize visual acuity. These advanced technologies ensure that modern polycarbonate lenses deliver superb optical clarity, providing crisp, clear vision without compromise.

Lightweight Design and Enhanced Comfort

The physical comfort of your eyewear directly impacts your daily satisfaction. Polycarbonate lenses are a game-changer in this regard, offering a remarkably lightweight and thin profile that enhances the overall wearing experience.

The Advantage of Lightweight Polycarbonate Frames

Imagine wearing eyeglasses all day without feeling their presence. This is the reality for users of lightweight polycarbonate eyewear. Compared to traditional glass or even standard plastic, polycarbonate significantly reduces the overall weight of your frames and lenses. This reduction directly translates into enhanced comfort, as it minimizes pressure points on the nose bridge and behind the ears.

This reduced weight contributes profoundly to overall user satisfaction. Heavy eyewear can cause discomfort, headaches, and even leave marks on your face. By choosing polycarbonate eyeglasses, wearers experience unparalleled comfort for extended wear, making them forget they’re even wearing glasses. This comfort eyewear ensures your daily activities are unimpeded by cumbersome frames.

Are Polycarbonate Lenses Thin?

Beyond their lightness, polycarbonate lenses are also inherently thinner than standard plastic lenses, especially for higher prescriptions. So, are polycarbonate lenses thin? Absolutely. Their higher refractive index means they can bend light more efficiently, requiring less material to achieve the same corrective power. This slim profile contributes to a more aesthetically pleasing appearance, particularly for individuals with strong prescriptions who might otherwise have thick, bulky lenses.

This lens thickness advantage impacts the overall feel and balance of the eyeglasses. Thinner polycarbonate lenses sit more flush within the polycarbonate frames, creating a sleek, streamlined look. This not only enhances cosmetic appeal but also improves the balance of the eyewear, preventing them from feeling front-heavy or unwieldy. The combination of being lightweight and thin solidifies polycarbonate eyeglasses as a premium choice for both comfort and style.

For a comprehensive selection of polycarbonate eyeglasses that combine superior safety, advanced UV protection, and unparalleled comfort, explore the latest collections. Discover how polycarbonate can revolutionize your vision experience by visiting polycarbonate frames and lenses, where you can find options designed for durability, clarity, and daily wear.

Polycarbonate Lenses Pros and Cons: A Balanced View

While the previous section highlighted the compelling advantages of polycarbonate eyeglasses, a truly informed decision requires a balanced perspective. Like any material, polycarbonate lenses come with their own set of considerations. This section provides an objective look at both the significant benefits and the nuances that potential wearers should be aware of, helping you weigh the options for your vision correction needs in 2025.

Advantages That Make a Difference

The widespread adoption of polycarbonate as a leading eyeglass lens material is rooted in several undeniable strengths. These advantages directly address core consumer needs for safety, protection, and comfort, making polycarbonate eyewear a preferred choice for many.

Key Strengths of Polycarbonate Eyeglasses

First and foremost, the unrivaled impact resistance of polycarbonate lenses ensures robust safety for your eyes. As previously discussed, their ability to withstand significant force and projectiles, meeting stringent standards like ANSI Z87.1, makes them ideal protective eyewear for active individuals and children. This durability provides unparalleled peace of mind, dramatically reducing the risk of lens-related eye injuries.

Beyond physical protection, polycarbonate offers built-in, comprehensive UV protection, negating the need for additional coatings to shield your eyes from harmful solar radiation. These polycarbonate lenses naturally block nearly 100% of UVA and UVB rays, a critical feature for long-term eye health and protection against sun-related conditions. This integrated UV block is a distinct advantage, ensuring continuous eye safety without extra steps.

Furthermore, the lightweight and thin design of polycarbonate significantly enhances wearer comfort and aesthetic appeal. Their higher refractive index allows for a slimmer profile, especially for those with stronger prescriptions, resulting in lenses that are noticeably thinner and lighter than conventional options. This reduced weight minimizes pressure points, providing comfort eyewear that can be worn all day without fatigue.

Collectively, these attributes contribute to the overall durability of polycarbonate eyewear in various conditions. From resisting impacts on the sports field to enduring daily wear and tear, polycarbonate eyeglasses are engineered for resilience, ensuring they maintain their integrity and provide reliable vision correction over time.

Addressing the Disadvantages of Polycarbonate Lenses

While polycarbonate boasts impressive strengths, it’s equally important to understand its limitations. These are typically minor considerations for most users but can be significant for others, depending on their specific needs and expectations.

The Scratch Sensitivity Challenge

One of the most frequently discussed drawbacks of polycarbonate lenses is their scratch sensitivity. Inherently, polycarbonate is a softer material than traditional glass or even CR-39 plastic, making its surface prone to scratching from everyday abrasions. This means that without proper protection, polycarbonate glasses can accumulate scratches more easily, potentially impacting visual clarity over time.

This inherent softness is why scratch resistance polycarbonate lenses coatings are almost always applied by manufacturers. These hard coats are a standard industry practice, forming a protective layer over the lens surface to significantly improve its durability against minor abrasions. For instance, reputable eyewear brands ensure their polycarbonate lenses come standard with robust scratch-resistant coatings.

However, what happens when budget options, such as some safety glasses like Radians Mirage, lack this essential coating or apply a minimal one? Lenses without an adequate scratch resistance layer can quickly become marred, leading to diminished clarity and a significantly reduced lifespan for the eyewear. This underscores the importance of inquiring about anti-scratch coatings when purchasing polycarbonate eyeglasses.

Optical Quality Nuances

Another area of discussion regarding polycarbonate lenses pertains to their optical quality nuances. While modern polycarbonate delivers very good optical clarity that is perfectly sufficient for the vast majority of users and prescription eyeglasses, it can be marginally lower than glass or CR-39 plastic, particularly in specific scenarios. This subtle difference is often attributed to a slightly higher level of chromatic aberration (color fringing at the edges of objects) in polycarbonate compared to these alternative materials.

For individuals with strong prescriptions, the question arises: does this slight difference matter? For very high corrections, or for users with a high sensitivity to visual distortions, this marginal difference in optical clarity might be more noticeable, potentially causing slight discomfort or a perceived reduction in crispness, especially when looking through the periphery of the lens. This factor can influence user satisfaction and overall visual acuity. When considering the nuanced optical quality for complex prescriptions, the material choice can significantly influence both visual comfort and, inevitably, the prescription lenses price.

As a result, some users, particularly those with strong prescriptions or highly specific visual demands (such as certain Warby Parker customers), note a preference for high index lenses. High index materials can offer even thinner profiles for extreme prescriptions and often provide superior optical clarity with less chromatic aberration. This makes them a strong alternative for those prioritizing absolute visual precision above all else, providing an important comparative point for consumers evaluating polycarbonate against other advanced lens technologies.

Understanding both the unparalleled strengths and the subtle compromises of polycarbonate lenses empowers you to make an informed decision tailored to your lifestyle, visual needs, and budget. For a wide range of polycarbonate eyeglasses that balance these features, explore options that combine durability with clarity. Discover your perfect pair, whether prioritizing safety, style, or a combination of both, by visiting polycarbonate vision solutions, where you can find diverse collections offering robust protection and comfortable wear.

Polycarbonate in Comparison: Other Lens Materials

Understanding where polycarbonate eyeglasses stand among other lens materials is crucial for making an informed decision. While polycarbonate offers impressive advantages, a broader perspective reveals how other lens materials cater to different needs, preferences, and prescriptions. This section delves into direct comparisons, helping you identify the optimal eyewear solution for your unique requirements in 2025.

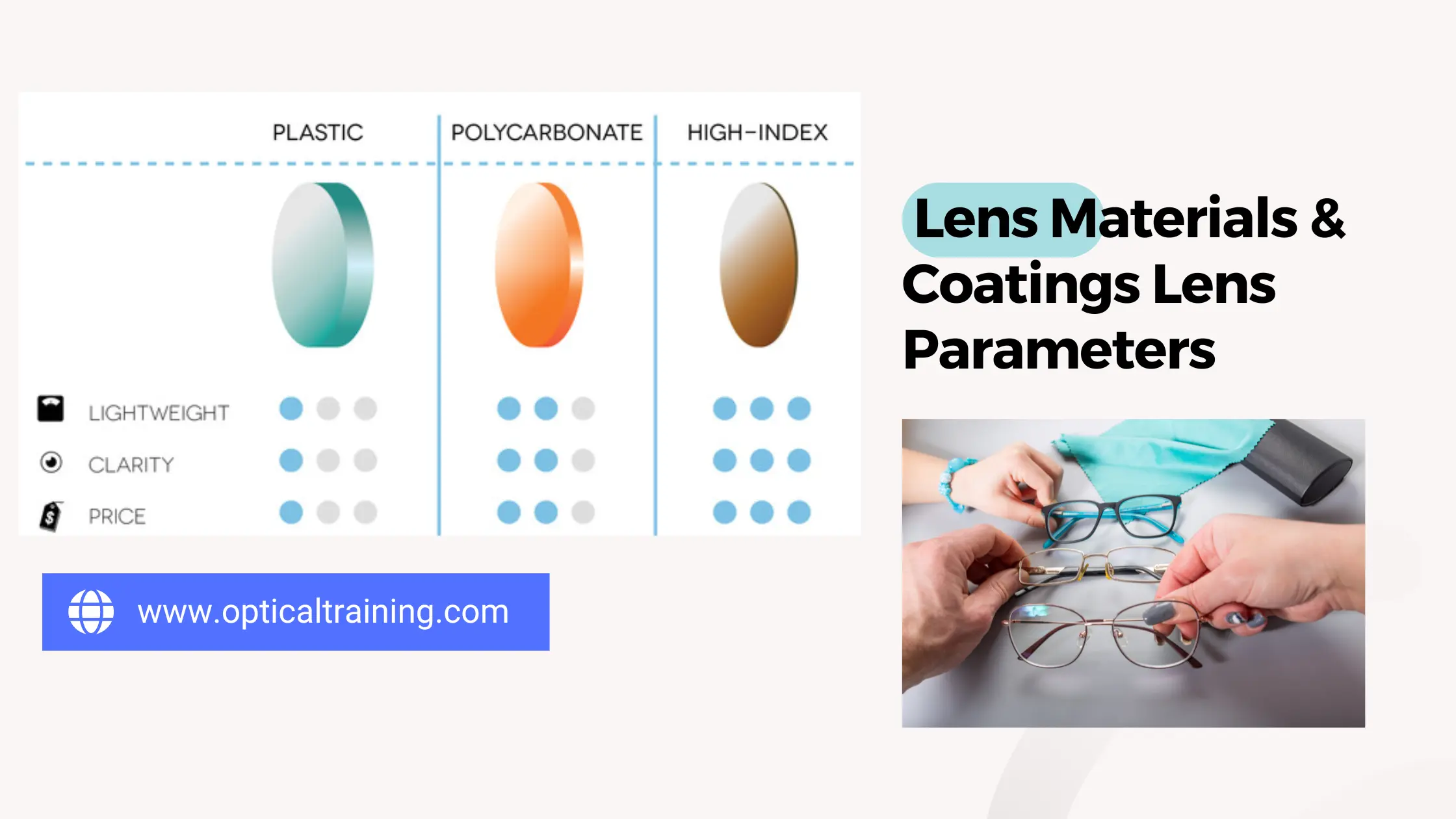

Polycarbonate vs. High Index Lenses

When seeking the slimmest and most discreet eyeglass lenses, high index materials often enter the conversation as a prime alternative to polycarbonate. Both aim to provide effective vision correction, but their approach to lens thickness and other properties differs significantly.

When Thinner is Better: High Index Options

For individuals with strong prescriptions, the pursuit of thinner lenses is a common priority. This is where high index lenses excel. Unlike standard polycarbonate, high index materials have a higher refractive index, meaning they bend light more efficiently. This allows for significantly thinner and lighter lens profiles even with considerable vision correction needs.

Specifically, 1.67 high index lenses offer a notable reduction in thickness compared to polycarbonate for moderate to strong prescriptions, while 1.74 high index lenses represent the pinnacle of thinness available today, ideal for the most extreme prescriptions. Retailers like Warby Parker, among other reputable eyewear providers, frequently offer these high index alternatives, catering to consumers who prioritize a minimalist aesthetic and reduced lens bulk above all else. These advanced lens options ensure a sleek look, even for those with significant myopia or hyperopia.

Performance vs. Thickness

While high index lenses win on thinness, how do they stack up against polycarbonate in terms of essential performance metrics? Polycarbonate remains the undisputed champion for inherent impact resistance, naturally meeting stringent safety standards like ANSI Z87.1. This makes polycarbonate eyeglasses the go-to for protective eyewear in active or hazardous environments. High index plastics, while durable, generally do not offer the same level of inherent impact protection without additional engineering, and their shatter resistance can vary.

Regarding UV protection, both polycarbonate and most modern high index lenses block nearly 100% of harmful UVA and UVB rays, often as a standard feature or through integrated UV coatings. The trade-off, then, primarily revolves around ultimate thinness versus established impact performance. Is achieving the thinnest lens profile your paramount concern, or does the robust, inherent impact resistance of polycarbonate offer greater peace of mind for your lifestyle? This lens material comparison highlights the need to weigh aesthetic preference against crucial safety features.

Polycarbonate vs. Trivex Lenses

Another close competitor to polycarbonate in the realm of impact-resistant lenses is Trivex. Developed in the early 2000s, Trivex shares many of polycarbonate‘s benefits, yet introduces distinct advantages, particularly concerning optical quality.

Siblings in Impact Resistance

Both polycarbonate and Trivex are highly regarded for their exceptional impact resistance, making them popular choices for physical eye protection across a wide range of applications, from children's glasses to safety eyewear. They are significantly more resistant to shattering than traditional plastic or glass lenses. However, their differences lie in their optical clarity and density.

Trivex lenses are often cited as having superior optical clarity compared to polycarbonate. This is primarily due to their lower Abbe value (less chromatic aberration), meaning they produce less “color fringing” at the edges of objects, resulting in a crisper, more natural field of vision, especially for sensitive wearers. Furthermore, Trivex is typically lighter and has a slightly lower density than polycarbonate, making it an excellent choice for extremely lightweight eyeglasses, particularly rimless frames or drill-mount frames where the material’s ability to resist chipping around drill holes is critical.

Choosing the Right Material for Your Needs

Are Trivex lenses genuinely clearer than polycarbonate, as some optical experts claim? For many users, the difference in optical clarity between polycarbonate and Trivex is imperceptible in daily wear. However, individuals with stronger prescriptions or those highly sensitive to visual distortions may indeed perceive Trivex as offering a slightly sharper and more comfortable viewing experience.

Specific scenarios often dictate which material is preferred:

- Trivex: Often chosen for

drill-mount framesdue to its superior resistance to cracking during drilling. Its enhancedoptical clarityalso makes it a favorite forchildren's eyewear, ensuring clear vision while maintaining highimpact protection. Somesafety glassesthat demand high optical precision might also opt forTrivex. - Polycarbonate: Remains a cost-effective choice for robust

safety glasses,sports eyewear, and everydayprescription eyeglasseswhereimpact resistanceandUV protectionare paramount and slightoptical nuancesare less of a concern. It provides excellent overall value and protection.

When weighing these material choices, it’s also worth considering how they impact the final cost of your eyeglasses. For those seeking value, exploring options for discount eyeglasses online can help you find quality polycarbonate or Trivex lenses within your budget without compromising on essential features.

Why Not Glass?

Before the advent of modern plastic lenses like polycarbonate and Trivex, glass lenses were the standard. While glass possesses certain advantages, its significant drawbacks have led to its decreased popularity for everyday prescription eyeglasses in 2025.

Pros and Cons of Traditional Glass Lenses

Traditional glass lenses are renowned for two primary strengths: unparalleled optical clarity and superior scratch resistance. Glass boasts an extremely high Abbe value, meaning virtually no chromatic aberration, providing the crispest and most precise vision correction possible. Furthermore, its inherent hardness makes it far less prone to scratching from daily wear and cleaning compared to polycarbonate or even most high index plastics. For individuals prioritizing absolute visual purity and lens durability against superficial damage, glass remains an ideal choice.

However, despite these advantages, glass lenses are considerably less common now for several compelling reasons:

- Weight:

Glassis significantly heavier than anyplastic lens material. This increasedlens weightcan lead to discomfort, pressure marks on the nose and ears, and a tendency foreyeglass framesto slide down, especially withstronger prescriptions. - Cost: Manufacturing

glass lenses, especially with specialized coatings or complex prescriptions, can be more expensive than their plastic counterparts. - Increased Risk of Shattering Upon Impact: This is the most critical disadvantage and a primary

safety concern. UnlikepolycarbonateorTrivex, which resist impact by deforming or absorbing energy,glasswill shatter into sharp, dangerous fragments when subjected to significant force. This poses a severerisk of eye injuryfrom projectiles or falls, makingglass lensesunsuitable forsafety eyewear,sports glasses, orchildren's eyeglassesaccording to moderneye safety standards.

Therefore, while glass offers optical precision and scratch durability, the overwhelming benefits of lightweight design, cost-effectiveness, and crucially, superior impact safety have solidified polycarbonate and other advanced plastic lenses as the dominant choices for vision correction in the contemporary eyewear market. For those prioritizing a balance of protection, comfort, and optical clarity, exploring a wide range of options in polycarbonate eyeglasses is highly recommended. Discover solutions tailored to your unique needs, from robust safety designs to lightweight daily wear options, by visiting polycarbonate eyewear collections, where you can find diverse collections offering robust protection and comfortable wear.

Beyond Everyday Wear: Polycarbonate Applications

While polycarbonate eyeglasses are a go-to for everyday vision correction, their exceptional properties extend far beyond standard daily wear. In 2025, polycarbonate is a cornerstone material for specialized eyewear, offering critical advantages in demanding environments and active lifestyles. From robust safety glasses that protect against hazards to high-performance sunglasses designed for outdoor adventures, polycarbonate lenses consistently deliver a superior combination of durability, lightweight comfort, and essential protection. This versatility highlights why polycarbonate is often the material of choice when specific performance characteristics are paramount. In fact, its adaptability even benefits specialized solutions like half lens reading glasses, where lightweight durability ensures comfort for prolonged use.

Polycarbonate Safety Eyeglasses: Essential Protection

For anyone working in hazardous conditions or engaging in DIY projects, polycarbonate safety eyeglasses are not merely an accessory; they are a vital piece of personal protective equipment. The inherent impact resistance of polycarbonate makes it the undisputed champion for protective eyewear, safeguarding vision from flying debris, chemicals, and impacts.

Meeting Industry Standards: ANSI Z87.1 Polycarbonate

The primary reason polycarbonate is the material of choice for compliant safety eyewear is its unparalleled ability to meet stringent safety standards. Specifically, polycarbonate lenses naturally satisfy the ANSI Z87.1 standard, which defines the requirements for occupational and educational eye and face protection devices. This standard mandates that safety lenses must be able to withstand high-velocity impacts and high-mass impacts without shattering.

Unlike traditional glass or standard plastics, polycarbonate absorbs energy upon impact, deforming rather than splintering. This shatterproof quality is critical for preventing severe eye injuries. Prominent examples of ANSI Z87.1 certified polycarbonate safety glasses include the 3M Virtua CCS series, known for its integrated cord control system, and the DeWalt DPG59-115C Reinforcer Rx-Bifocals, which combine impact protection with magnification for those needing reading assistance on the job. These protective glasses offer peace of mind in high-risk environments.

Real-World Polycarbonate Safety Glasses Reviews

User insights consistently underscore the importance of polycarbonate in safety eyewear. Reviews often highlight the comfort and fit of polycarbonate safety glasses as crucial for consistent wear, acknowledging that uncomfortable eyewear is often neglected eyewear. Users in construction, manufacturing, and even home renovation commend the effectiveness of these lenses in preventing eye injuries from dust, splinters, and chemical splashes.

Many DIY enthusiasts and professional tradespeople share anecdotes of close calls where their polycarbonate safety glasses saved their vision. This real-world performance reinforces the critical role of protective eyewear technology. The durability of polycarbonate also means these safety glasses withstand the rigors of daily work or DIY scenarios, offering a long-lasting, reliable solution for on-site safety.

Polycarbonate Sunglasses Benefits

Beyond their role in safety, polycarbonate sunglasses have become a dominant force in the outdoor and fashion eyewear markets. They merge superior protection with stylish designs, making them ideal for outdoor adventures and everyday wear.

Durability and UV Protection for Outdoor Adventures

When it comes to sunglasses for demanding environments, polycarbonate lenses are a natural fit. Their inherent durability means they are significantly more impact resistant than glass or standard plastic lenses, making them an excellent choice for sports sunglasses and outdoor eyewear. Whether you’re hiking, cycling, or enjoying water sports, polycarbonate can withstand accidental drops and impacts, ensuring your eyewear performs as reliably as you do.

Crucially, polycarbonate lenses also provide 100% UV protection against harmful UVA and UVB rays as a standard feature, without needing additional coatings. This comprehensive UV blocking is vital for long-term eye health, preventing conditions like cataracts and macular degeneration. Many polycarbonate sunglasses also incorporate polarization, which effectively reduces glare from reflective surfaces like water, snow, and roads. For instance, Kleenguard V30 Nemesis Polarized Safety Glasses (often used as safety sunglasses) demonstrate how polycarbonate combined with polarization offers enhanced visual clarity and comfort in bright conditions. This makes them perfect for fishing, driving, or any activity where glare reduction is beneficial.

Fashion Meets Function: Popular Polycarbonate Sunglasses

The versatility of polycarbonate extends to designer sunglasses, allowing brands to create stylish yet highly protective designs. Brands like Wiley X Founder utilize polycarbonate for robust performance eyewear that also looks great. Nathan Adventure Polarized sunglasses offer excellent glare reduction and durability for runners and adventurers, while Oakley Frogskins exemplify how polycarbonate can be used to create iconic lifestyle sunglasses that deliver both fashion and impact protection.

The question of suitability for high-impact sports versus casual wear often arises. While many polycarbonate sunglasses are designed with athletic eyewear in mind, offering a degree of impact resistance for general active use, those specifically certified for ANSI Z87.1 safety standards will provide the highest level of impact protection for true high-impact sports or hazardous activities. For most casual wear and moderate outdoor activities, the polycarbonate lenses found in popular fashion sunglasses provide ample durability and UV protection, making them a sensible and safe choice. To explore a wide array of polycarbonate eyeglasses that balance robust protection with contemporary style, discover diverse collections tailored to various needs: polycarbonate eyewear collections.

Caring for Your Polycarbonate Eyeglasses: Maintenance & Longevity

To truly maximize the value and performance of your polycarbonate eyeglasses, consistent and proper care is paramount. While polycarbonate is renowned for its durability and impact resistance, its lenses are still susceptible to scratches and damage from improper handling. In 2025, understanding the best practices for eyewear maintenance is key to ensuring your polycarbonate lenses maintain their optical clarity and protective qualities for years to come.

Cleaning Polycarbonate Lenses Without Scratching

One of the most frequent causes of damage to polycarbonate lenses is improper cleaning. The robust nature of polycarbonate eyewear doesn’t negate the need for a careful approach to keep them pristine and clear.

The Proper Cleaning Protocol

The first and most critical step in cleaning your polycarbonate lenses is to rinse them thoroughly under lukewarm water. Why is this so crucial? Dry wiping your eyeglass lenses can simply push abrasive dust particles and debris across the surface, effectively grinding them in and causing irreparable scratches. Water helps to dislodge and wash away these minute contaminants, preventing them from damaging the polycarbonate lens surface.

After rinsing, apply a small drop of an eyeglass-specific cleaning spray or a gentle, lotion-free dish soap to each lens. These solutions are formulated to effectively break down skin oils, smudges, and other residues without using harsh chemicals that could strip protective coatings from your polycarbonate eyewear. Gently rub the lenses and frame with your fingertips, ensuring all surfaces are covered.

Finally, rinse your eyeglasses again under lukewarm water to remove all traces of soap. The indispensable tool for drying and polishing your polycarbonate lenses is a clean, soft microfiber cloth. This specialized eyewear cloth is designed to absorb moisture and polish lenses without leaving lint or causing scratches, maintaining the optical clarity of your polycarbonate vision correction.

What to Avoid: Common Cleaning Mistakes

Understanding what not to do is just as important as knowing the proper cleaning techniques. Never use substances like acetone, window cleaners containing ammonia, or paper products (such as paper towels, tissues) on your polycarbonate lenses. Acetone and harsh chemical cleaners can severely strip anti-reflective or scratch-resistant coatings that are often applied to polycarbonate, leaving the lens vulnerable to damage and compromising its visual performance.

Similarly, using paper towels, tissues, or even the fabric of your shirt might seem convenient, but these materials are too abrasive. They often contain wood fibers or rough textures that can create micro-scratches on your polycarbonate lens surface over time. These seemingly minor scratches accumulate, leading to a hazy appearance and significantly reduced optical clarity. This directly impacts the scratch resistance of your polycarbonate lenses and shortens their functional lifespan.

How Long Do Polycarbonate Glasses Last?

While polycarbonate glasses are highly regarded for their durability, they are not impervious to wear and tear. Understanding their expected lifespan and how protective coatings contribute to their longevity is vital for eyeglass wearers.

Expected Lifespan and When to Replace

Generally, the lifespan of polycarbonate eyeglasses can range from 3 to 5 years, or even longer, depending on the level of care they receive and how frequently they are worn. Factors such as consistent exposure to extreme temperatures, harsh chemicals, or frequent drops can significantly shorten this duration. The resilience of polycarbonate eyewear is impressive, but it’s not indestructible.

Immediate replacement is necessary if your polycarbonate lenses or frame suffer significant damage, such as a large crack, deep scratches that impede vision, or a severely bent frame that compromises the fit. Furthermore, if your prescription changes, it’s crucial to obtain new polycarbonate eyeglasses that match your updated vision correction needs. Wearing an outdated prescription can lead to eye strain and discomfort. If your prescription changes, or if you’re looking for an upgrade, remember that investing in new prescription sunglasses can also offer enhanced visual comfort and protection, especially if you find great deals.

Impact of Scratch Resistance Coating on Durability of Polycarbonate Eyewear

One of the most significant factors influencing the durability of polycarbonate eyewear is the scratch-resistant coating. Polycarbonate material itself is inherently softer than glass, making it more prone to surface scratches. This is why virtually all polycarbonate lenses come with a hard coating (also known as a scratch-resistant coating) applied during manufacturing.

How effectively do these coatings prolong the useful life of polycarbonate lenses? These protective layers act as a crucial barrier, preventing minor abrasions from daily handling, wiping, and exposure to dust. They significantly enhance the resilience of the lenses, maintaining optical integrity and clarity. Without this coating, polycarbonate lenses would quickly become marred, obscuring vision and necessitating premature replacement.

What happens when the coating wears off? Over time, even the best scratch-resistant coatings can degrade or wear thin due to repeated cleaning, chemical exposure, or physical abrasion. When the coating wears off, the underlying polycarbonate is exposed, making the lens far more susceptible to scratches. This can lead to a noticeable reduction in clarity, increased glare, and a generally impaired visual experience. This degradation directly impacts the durability and functional lifespan of your polycarbonate lenses, highlighting the importance of proper eyewear care.

Maximizing Durability of Polycarbonate Eyewear

Extending the lifespan of your polycarbonate eyewear beyond general expectations is entirely achievable with a few proactive measures. These maintenance tips not only keep your polycarbonate glasses looking new but also ensure they continue to provide optimal vision protection and clarity.

Tips for Prolonging the Life of Your Glasses

- Consistent, gentle cleaning practices. As detailed previously, adhering to the

proper cleaning protocolis the single most effective way to prevent premature wear. Regularly cleaning yourpolycarbonate lenseswith lukewarm water, appropriate cleaning solutions, and amicrofiber clothprevents the build-up of grime and the accumulation ofscratches. This routine diligence directly contributes to maintaininglens clarityand extending thedurabilityof yourpolycarbonateinvestment. - Always storing your eyeglasses in a protective case when not in use. This is perhaps the most overlooked yet vital

eyewear caretip. Simply placing yourpolycarbonate eyeglasseson a table, bedside stand, or in your bag without a case exposes them to an array of hazards. Ahard shell caseprovides essential protection against crushing, bending, and accidentalscratchesto bothlensesandframe. For more casual storage, asoft pouchcan protect against surfacescratchesbut offers less impact protection. Making a habit of storing yourpolycarbonate eyewearsafely whenever they’re not on your face drastically prolongs theirlifespan. - Regular checks for loose screws or frame integrity. Periodically inspect your

polycarbonate eyeglassesfor any loose screws, especially around the hinges and nose pads. Tightening these small components with a tinyeyeglass screwdrivercan prevent larger issues, such aslensespopping out orframesbecoming misaligned. Also, check theframefor any signs of stress cracks or bends. Addressing these minorframe issuesearly can prevent more significant damage and avoid costlyrepairsorreplacements. Proactiveeyewear maintenanceensures yourpolycarbonate glassesremain comfortable and functional for as long as possible. To explore a wide array ofpolycarbonate eyeglassesthat balance robust protection with contemporary style, discover diverse collections tailored to various needs: polycarbonate eyewear collections.

Choosing Your Perfect Pair of Polycarbonate Eyeglasses

Having understood the comprehensive care and longevity factors for your existing polycarbonate eyeglasses, the next crucial step is making an informed decision when selecting a new pair. In 2025, the market offers a vast array of polycarbonate eyewear, and choosing the ideal one requires careful consideration of safety standards, fit, lens treatments, and prescription requirements. This section will guide you through the key considerations to ensure your new polycarbonate glasses perfectly meet your vision and protection needs.

Key Considerations for Buyers

When you’re in the market for new polycarbonate eyewear, it’s not just about aesthetics. Your choice significantly impacts your eye safety and visual comfort. Focusing on these key considerations will help you pinpoint the perfect pair of polycarbonate lenses.

Protection Standards (ANSI, MILSPEC)

For anyone considering polycarbonate eyeglasses, especially for work or active lifestyles, understanding protection standards is paramount. Polycarbonate is renowned for its exceptional impact resistance, making it the material of choice for safety glasses and protective eyewear.

Why checking for ANSI Z87.1 polycarbonate certification is paramount for safety? The ANSI Z87.1 standard is the American National Standard for occupational and educational personal eye and face protection devices. When polycarbonate lenses are ANSI Z87.1 certified, it signifies they have undergone rigorous testing for high-mass impact, high-velocity impact, and optical clarity. This certification assures users that their polycarbonate safety glasses can withstand significant blunt force trauma or fast-moving projectiles, dramatically reducing the risk of eye injury. It’s a non-negotiable feature for protective eyewear in hazardous environments.

What MIL PRF-31013 certification signifies for ballistic protection? Beyond standard industrial safety, some polycarbonate eyewear meets military ballistic protection standards. The MIL PRF-31013 specification is a U.S. military standard for spectacles, ensuring they can withstand high-velocity fragmentation from sources like explosions or gunfire. While typically for military and law enforcement, this certification is sometimes found in high-end protective eyewear for civilians seeking the ultimate ballistic resistance. If you require extreme impact protection, seeking polycarbonate lenses with this military-grade rating offers unparalleled safety.

Fit and Comfort

Even the most protective polycarbonate lenses are ineffective if they’re not worn consistently, and that hinges entirely on fit and comfort. The importance of lightweight polycarbonate frames, adjustable temples, and comfortable nose pads for all-day wear cannot be overstated. Polycarbonate itself is a very lightweight lens material, which contributes significantly to overall eyewear comfort. Paired with lightweight frames made from materials like titanium or TR-90, polycarbonate glasses can be worn for extended periods without causing pressure points or discomfort. Adjustable temples (the arms of the glasses) allow for a customized fit around the ears, preventing slipping, while comfortable nose pads ensure the eyewear rests gently on the bridge of the nose, distributing weight evenly and avoiding red marks or irritation.

Does a better fit mean better protection and durability? Absolutely. A secure fit ensures your polycarbonate safety glasses stay in place, providing continuous protection against hazards. If glasses constantly slip down your nose or feel too tight, you’re less likely to wear them, or you might frequently adjust them, increasing the risk of dropping or damaging them. A properly fitting pair of polycarbonate eyeglasses is also less prone to frame bending or lens dislodgement from accidental impacts, directly contributing to their durability and functional lifespan. It’s an ergonomic design principle that translates directly to enhanced longevity and safety.

Lens Treatments

While polycarbonate lenses inherently offer UV protection and impact resistance, various lens treatments further enhance their performance and longevity. Understanding the value of scratch resistance polycarbonate lenses coatings, anti-fog, and polarization is crucial for selecting your ideal eyewear.

Scratch-resistant coatings are virtually standard on all polycarbonate lenses because the polycarbonate material itself is softer than glass and more prone to surface abrasions. This hard coating acts as a protective barrier, significantly extending the durability and optical clarity of your polycarbonate eyewear by preventing minor scratches from daily wear and cleaning. Without it, your vision would quickly become obscured.

Anti-fog coatings are invaluable for polycarbonate glasses used in environments with significant temperature changes or high humidity. These treatments prevent condensation from forming on the lenses, ensuring clear vision whether you’re transitioning from cold outdoors to a warm indoor space, working in a humid environment, or wearing a mask. This enhances both safety and comfort.

Polarized lenses, often applied to polycarbonate sunglasses, are designed to reduce glare from reflective surfaces like water, snow, or roads. They contain a special filter that blocks horizontal light waves, allowing only vertical light waves to pass through. This results in crisper vision, reduced eye strain, and enhanced visual comfort, especially during outdoor activities. How do these treatments enhance both performance and longevity? By protecting the lenses from damage (scratch resistance), ensuring uninterrupted clarity (anti-fog), and improving visual comfort (polarization), these coatings ensure your polycarbonate glasses perform optimally for a longer period, making them a wise investment.

Prescription Needs

One of the greatest advantages of polycarbonate lenses is their versatility, especially when it comes to prescription needs. Exploring options for prescription polycarbonate eyeglasses, including bifocal and progressive designs, highlights this adaptability. Polycarbonate is an excellent choice for prescription lenses due to its thin and lightweight nature, even for higher prescriptions. This means more comfortable eyewear that doesn’t add unnecessary bulk. For those with multiple vision needs, polycarbonate can be seamlessly integrated into bifocal lenses (offering two distinct focal points) or progressive lenses (providing a smooth, seamless transition between distance, intermediate, and near vision without visible lines). This allows eyeglass wearers to enjoy comprehensive vision correction with the added safety benefits of polycarbonate.

Furthermore, considerations for polycarbonate glasses for kids with specific vision needs are crucial. Children are highly active and prone to accidental impacts, making polycarbonate the safest lens material due to its unmatched impact resistance. Whether a child requires standard single-vision lenses or specialized options like half lens reading glasses for schoolwork, polycarbonate provides peace of mind for parents, significantly reducing the risk of lens breakage and potential eye injury. Choosing polycarbonate for children's eyewear ensures their eyes are well-protected while their vision correction needs are met. For specific deals on children’s eyewear or to explore options for reading assistance, you might find valuable insights by exploring guides on how to score big savings on half lens reading glasses.

Budget vs. Investment: Are Expensive Polycarbonate Eyeglasses Worth It?

When evaluating polycarbonate eyeglasses, the price spectrum can be wide, leading many to question if investing in more expensive options truly pays off. This section examines the value proposition of premium polycarbonate eyewear and helps you make an informed financial decision.

Value Proposition of Premium Polycarbonate Eyewear

Why higher-priced options often boast superior lens quality, sturdier frames, and more durable hinges? The cost difference in polycarbonate eyeglasses often reflects a significant upgrade in materials and manufacturing processes. Premium polycarbonate lenses might feature more advanced anti-reflective (AR) coatings that truly eliminate glare and reflections, enhancing optical clarity and visual comfort. They may also integrate hydrophobic and oleophobic treatments that repel water and oils, making lenses easier to clean and thus prolonging their scratch resistance.

Beyond the lenses, the frames of premium polycarbonate eyewear are typically crafted from higher-grade materials like aerospace-grade titanium, high-quality acetate, or advanced polymers, which offer superior flexibility, strength, and longevity. This translates to frames that maintain their shape better, resist breaking, and withstand daily wear and tear more effectively. Crucially, more durable hinges, often made from high-quality metal alloys and designed for smoother operation and greater resilience, are a hallmark of premium eyeglasses. These small components are frequent points of failure in cheaper glasses.

Consider product testing examples like Costa Del Mar Pescadors lasting over 4 years of regular, hard use. Such anecdotal evidence, backed by user testimonials and expert reviews, often highlights that the initial investment in a premium pair pays dividends in terms of extended lifespan, consistent performance, and overall satisfaction. This means fewer replacements and a more reliable vision correction tool.

Making an Informed Decision

Ultimately, making an informed decision about polycarbonate eyeglasses involves weighing the initial cost against long-term durability and optical performance. While it’s tempting to opt for the cheapest polycarbonate glasses available, considering the lifespan of the product, the quality of your vision, and your safety needs is essential.

When is investing in top-tier Eyewear Technology a smart financial move? It becomes a smart financial move if:

- You wear your

eyeglassesdaily and rely on them for essential activities. - Your profession or hobbies expose your

eyewearto challenging conditions. - You value

superior optical clarityandreduced eye strain. - You want

eyeglassesthat will last longer, reducing the frequency and cost ofreplacements. - You prioritize

eye protectionabove all else.

Choosing premium polycarbonate eyewear can be seen as an investment in your vision health and comfort. While the upfront cost might be higher, the enhanced durability, superior optical quality, and reduced need for frequent replacements can often lead to greater value over the long term. For a comprehensive selection of polycarbonate eyeglasses that meet various budget and performance needs, consider exploring diverse collections online. You can find options that balance robust protection with contemporary style and cutting-edge lens technology by visiting polycarbonate eyeglasses.

The Clear Choice: Embracing Polycarbonate Eyewear for Superior Vision and Safety

In conclusion, polycarbonate eyeglasses stand out as a revolutionary material in the optical industry, offering a comprehensive solution for modern eyewear needs. From their inception as aerospace technology, polycarbonate lenses have redefined expectations for safety, comfort, and durability in daily vision correction.The core advantages are undeniable: unmatched impact resistance, making them the safest choice for active individuals, children, and demanding work environments, often meeting stringent ANSI Z87.1 and even MIL-PRF-31013 ballistic standards. This robust protection is seamlessly integrated with inherent 100% UV blocking, safeguarding your long-term eye health without the need for additional coatings. Furthermore, their lightweight and thin profile significantly enhances wearer comfort, reducing pressure points and offering a sleek aesthetic, particularly beneficial for higher prescriptions where traditional lenses can appear bulky.While polycarbonate offers exceptional value, a balanced perspective acknowledges nuances. Its natural scratch sensitivity necessitates high-quality scratch-resistant coatings, which are now standard across reputable manufacturers, ensuring sustained optical clarity. While some high-index lenses might offer marginally thinner profiles for extreme prescriptions or Trivex provides slightly higher optical clarity for discerning users, polycarbonate consistently delivers a superior blend of performance, safety, and cost-effectiveness that satisfies the vast majority of wearers. Unlike traditional glass, which poses significant weight and shattering risks, polycarbonate offers a decisively safer and more comfortable alternative.Beyond everyday wear, polycarbonate’s versatility shines in specialized applications. It is the gold standard for polycarbonate safety glasses, providing essential protection against industrial hazards, and an ideal material for polycarbonate sunglasses, combining durability with full UV protection and often glare-reducing polarization for outdoor adventures.To maximize the lifespan of your polycarbonate investment, proper care is crucial. Gentle cleaning with lukewarm water, appropriate solutions, and a microfiber cloth, coupled with diligent storage in a protective case, will maintain their optical integrity and scratch resistance. Regular checks for frame integrity further ensure longevity.When choosing your next pair, consider the critical balance of protection standards, a comfortable and secure fit, the benefits of advanced lens treatments like anti-fog and polarization, and how the material seamlessly integrates with your specific prescription needs, from single vision to progressive designs. Investing in quality polycarbonate eyewear is an investment in your long-term eye health, comfort, and safety. Explore the diverse range of polycarbonate eyeglasses available today to find a solution that perfectly matches your lifestyle and provides unparalleled visual confidence.

Leave a Reply